At Wegner industry , our only focus is custom doctor blade solutions. That’s why our blades, holders, and systems have a worldwide reputation for high performance, durability, and overall value.

Wegner doctor blades are vital components in many manufacturing processes. They enhance product quality by improving production with precise metering and materials control.

Whether they are called doctor blades in pulp and paper making or described as blades in metals, food, and other material processing applications, Wegner combines material performance and blade geometry with process knowledge to engineer system solutions that are quantifiable and cost-effective.

Carbon fiber is a leading choice for applications that require a strong, long-lasting doctor blade. Wegner carbon fiber blades combine stiffness and high corrosion resistance for improved lifecycle costs.

Fiberglass blades combine excellent roll-cleaning performance with superior wear-resistance. Fiberglass blades can also incorporate custom laminates engineered to meet the specific needs of just about any application.

Abrasive blades offer excellent cleaning performance for oscillating applications, such as press doctor trailing positions or in the dryer section.

Plastic blades provide cost-effective options for applications that require less rigidity, such as water removal.

| Material | Performance | Size | Features | Rivet | |

|---|---|---|---|---|---|

|

Carbon Fiber | Temperature resistance up to 180 ℃, corrosion resistance, low friction coefficient, wear resistance. | * Scrapers of other widths and thicknesses can be tailored to specific requirements. | According to the specification requirements, the single or double-edge blade angle is from 15 to 90 degrees and can be grooved. | Suitable rivets, gaskets, buckles, gaskets and spring pieces can be pre-assembled according to the type of scraper clamp. Or specially slotted to fit various types of scraper clamps. |

|

Fiberglass | Temperature resistance up to 120 degrees Celsius, corrosion resistance. | * Scrapers of other widths and thicknesses can be tailored to specific requirements | According to the specification requirements, the single or double-edge blade angle is from 15 to 90 degrees and can be grooved. | Suitable rivets, gaskets, buckles, gaskets and spring pieces can be pre-assembled according to the type of scraper clamp. Or specially slotted to fit various types of scraper clamps. |

|

Abrasive | Temperature resistance up to 180 degrees Celsius, corrosion resistance, good wear resistance. | * Scrapers of other widths and thicknesses can be tailored to specific requirements | According to the specification requirements, the single or double-edge blade angle is from 15 to 90 degrees and can be grooved. | Suitable rivets, gaskets, buckles, gaskets and spring pieces can be pre-assembled according to the type of scraper clamp. Or specially slotted to fit various types of scraper clamps. |

|

Plastic | Temperature and corrosion resistance up to 65 degrees Celsius. | * Scrapers of other widths and thicknesses can be tailored to specific requirements | Economical: According to the specification requirements, the single or double-edge blade angle is from 15 to 90 degrees and can be grooved. | Suitable rivets, gaskets, buckles, gaskets and spring pieces can be pre-assembled according to the type of scraper clamp. Or specially slotted to fit various types of scraper clamps. |

|

Cotton Fiber | Temperature resistance up to 140 degrees Celsius, corrosion resistance, good wear resistance. | * Scrapers of other widths and thicknesses can be tailored to specific requirements | According to the specification requirements, the single or double-edge blade angle is from 15 to 90 degrees and can be grooved. | Suitable rivets, gaskets, buckles, gaskets and spring pieces can be pre-assembled according to the type of scraper clamp. Or specially slotted to fit various types of scraper clamps. |

|

HDPE | Temperature and corrosion resistance up to 80 degrees Celsius. | * Scrapers of other widths and thicknesses can be tailored to specific requirements | Economical: According to the specification requirements, the single or double-edge blade angle is from 15 to 90 degrees and can be grooved. | Suitable rivets, gaskets, buckles, gaskets and spring pieces can be pre-assembled according to the type of scraper clamp. Or specially slotted to fit various types of scraper clamps. |

| Blade Appearance and Symptoms | Probable Causes | Remedy |

|---|---|---|

UNEVEN WEAR - Frequent blade change

|

A. Poor roll surface. B. Damaged or dirty blade holder. C. Deposits. |

A. Use more flexible blade. B. Clean, repair or replace holder. C. Use abrasive blade. |

EXCESSIVE WEAR IN CENTER OF BLADE, OR AT ENDS

|

A. Doctor not machined to roll crown. B. Old doctor sagging into/away from roll. |

A. Refit and shim holder to doctor back as

necessary. (Return new doctor for replaning

if mismatch is excessive.) B. Replace old, sagging doctor. |

EXCESSIVE WEAR ON ONE END

|

A. Doctor misaligned – not parallel to roll axis. | A. Shim, or move bearings and brackets as necessary to align doctor parallel to axis of roll. |

EVEN WEAR BUT ROUGH EDGE

|

A. Deposits on roll. B. Excessive pressure on blade. C. Blade material too hard. |

A. Use abrasive blade as required. B. Reduce pressure. C. Use softer blade. |

EXCESSIVE WEAR IN SHEET RUN

|

A. Deposits left on roll by sheet. | A. Use abrasive blade as required. B. Trim blade edges frequently. C. Use end slotted blades to prevent build-up of excessive pressure on roll ends. |

EXCESSIVE WEAR OUTSIDE SHEET

|

A. Sheet lubricates roll. | A. Slot blade ends to relieve pressure. |

LOCALIZED PITTING

|

A. Blade attacked by (1) Electrostatic Discharge, (2) Electrolysis, (3) Heat. | A. Insulate doctor from machine frame or use non-metalic blade. |

BLADE DEVELOPS FEATHERED EDGE

|

A. Blade material too soft. B. Excessive pressure. C. Blade angle too flat. |

A. Use harder blade. B. Reduce pressure. C. Move bearings or brackets to increase angle. Check for correct angle with gauge. |

HOOKS ON BLADE OUTSIDE ROLL SURFACE

|

Blade overhangs roll. A. Not centered. B. Too long. C. Not oscillating properly. |

A. Center blade. B. Trim length. C. Adjust oscillation stroke. |

DENT IN BLADE EDGE

|

A. Blade caught scab on roll at start-up. (Most common on old dryers.) | A. Change blade and remove scab. |

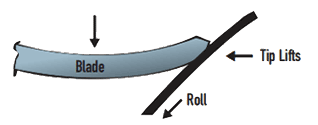

INCREASING PRESSURE INCREASES DEFLECTION

|

A. Blade pressure changed after initial wear-in; opens blade tip to trap particles and lift blade – may cause wrap | A. Reduce blade pressure or change blade. |

NOTE: ALWAYS INSPECT WORN BLADES FOR CLUES TO ANY PROBLEMS.

Wegner’s experts can help you achieve significant operational savings in any type of paper production–CWF, LWC, packaging board and others—with original high-performance Ceramics coating blades. Ceramic coating blades are factory-honed to each customer’s individual requirements. Proven to last up to 10 times longer than conventional steel blades, they wear smoothly and evenly to maintain excellent coatweight profiles. With specific tip materials to enhance coatweight application, smoothness, gloss and fiber coverage, Ceramic coating blades are customized to meet your needs.

Essco doctor blades and scraper blades are vital components in a wide range of manufacturing processes. They enhance product quality by improving production with precise metering and materials control.

Sign up for industry alerts, our latest news, thoughts and insights from Essco.

Fill out the form below.

"*" indicates required fields